Table of Contents

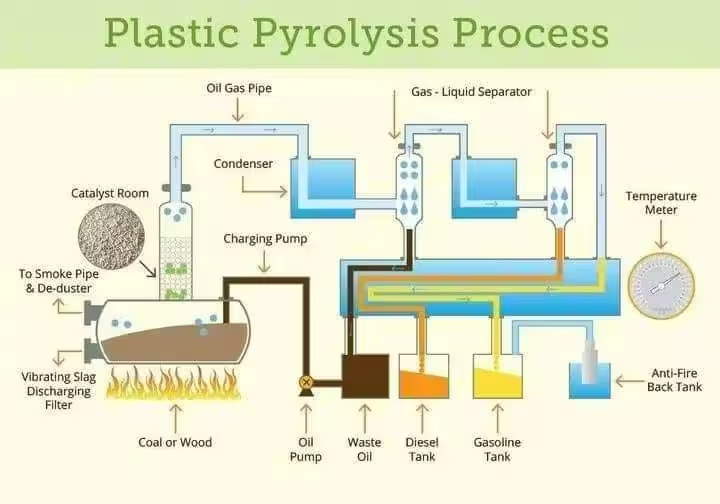

In the ever-evolving quest to find sustainable solutions for plastic waste, the plastic pyrolysis process has emerged as a promising technology. This process effectively converts plastic waste into valuable fuel products like diesel, gasoline, and waste oil. The diagram above illustrates the workings of a plastic pyrolysis plant, showing how plastic waste can be transformed into usable energy sources. Let’s delve into the steps of this process, the benefits, and some frequently asked questions.

What is Plastic Pyrolysis?

Plastic pyrolysis is a chemical recycling technique where plastic waste is heated in the absence of oxygen, leading to thermal decomposition. This method breaks down long plastic polymers into shorter hydrocarbon chains, producing a mix of fuel oil, gas, and char, depending on the plastic’s composition and the pyrolysis conditions.

The Plastic Pyrolysis Process Explained

The diagram illustrates the following key steps of the plastic pyrolysis process:

- Feed stock Preparation: The process starts with plastic waste, which is fed into the Catalyst Room for treatment. A catalyst is used to optimize the breakdown of plastic into smaller hydrocarbons.

- Pyrolysis Chamber: The plastic is heated in the pyrolysis chamber (using coal or wood as the heat source) without oxygen. This initiates the thermal decomposition process, where plastic turns into vapor and char.

- Oil and Gas Separation: The vapor produced moves through the Oil Gas Pipe to the Condenser, where it cools and condenses into liquid fuel (oil). Uncondensed gas continues to the Gas-Liquid Separator, ensuring proper separation of liquids and gases.

- Fuel Storage: The resulting fuels—diesel, gasoline, and waste oil—are collected and stored in their respective tanks. An oil pump transfers these products to storage or for further use.

- Temperature Control and Safety: The process includes a temperature meter for monitoring, and an anti-fire back tank ensures safety by preventing fires or explosions.

- By-products: Solid residues like char (or slag) are discharged through the vibrating slag discharging filter. Any remaining gases are directed to a smoke pipe and de-duster for filtration, ensuring environmental compliance.

Benefits of Plastic Pyrolysis

- Waste Management: The process offers a solution to the growing problem of plastic waste by converting it into usable fuels, reducing landfill dependency.

- Energy Production: Pyrolysis produces diesel and gasoline, which can be utilized in industries or transportation, promoting a circular economy.

- Reduced Emissions: Compared to incineration, pyrolysis emits fewer harmful gases and helps manage plastic waste in an environmentally friendly manner.

- Recyclable Products: The char produced during pyrolysis can be used in various applications, adding to the process’s value.

Frequently Asked Questions (FAQs)

Q1: What types of plastic can be used in the pyrolysis process?

A: Most plastic types, including polyethylene (PE), polypropylene (PP), and polystyrene (PS), are suitable for pyrolysis. However, PVC is typically avoided due to harmful by-products.

Q2: What are the main products of the plastic pyrolysis process?

A: The process primarily produces liquid fuels like diesel and gasoline, gases (syngas), and solid residues (char).

Q3: How is pyrolysis different from incineration?

A: Pyrolysis decomposes plastic waste in the absence of oxygen, producing fuels, whereas incineration burns plastic waste in the presence of oxygen, often resulting in more pollutants.

Q4: Is plastic pyrolysis environmentally friendly?

A: Yes, pyrolysis is considered more environmentally friendly than traditional plastic disposal methods like landfilling and incineration because it generates reusable energy and reduces greenhouse gas emissions.

Q5: What safety measures are in place for the pyrolysis process?

A: The process incorporates safety features such as temperature meters for monitoring, anti-fire back tanks to prevent fire hazards, and a de-duster to manage emissions.

The plastic pyrolysis process is a game-changer in managing plastic waste and converting it into valuable energy sources. With proper implementation, this process can significantly reduce plastic pollution, contributing to a more sustainable future.

Other blogs: https://sleepingsirens.com

More on this topic: click here

Keywords: plastic pyrolysis process, plastic waste management, pyrolysis fuel production, sustainable plastic recycling, plastic to fuel conversion, pyrolysis technology, converting plastic into energy.

Hashtags: #PlasticPyrolysis #SustainableEnergy #WasteManagement #PlasticRecycling #CircularEconomy #GreenTechnology