Table of Contents

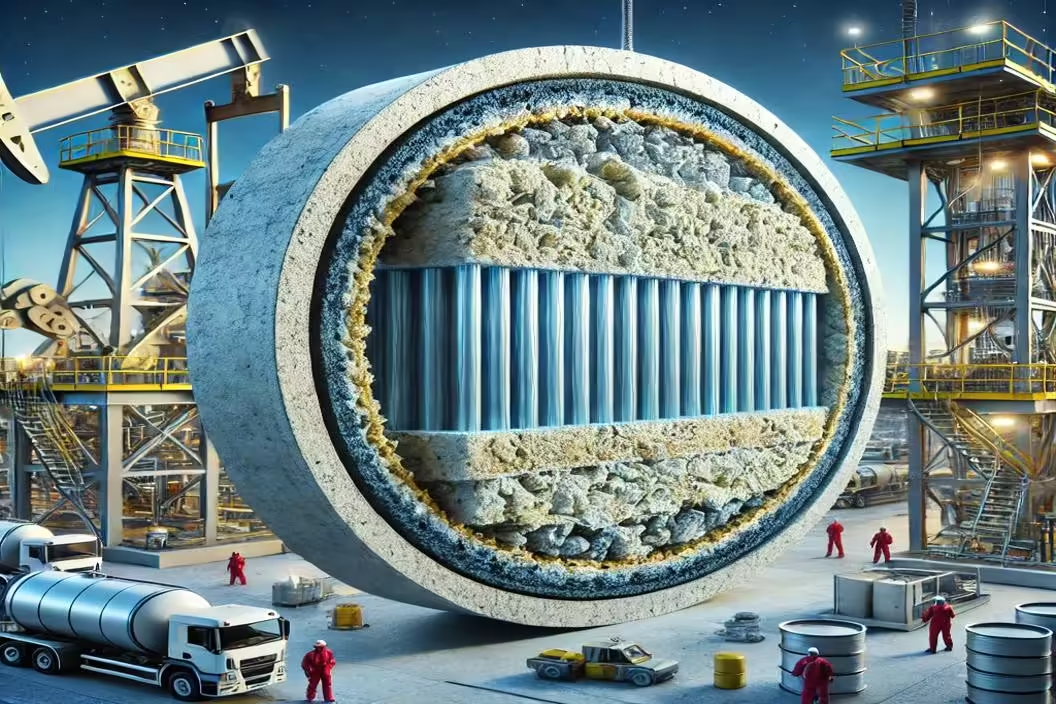

Material Made of Cement and Cross-Linked Polymer to Facilitate Insulation of Oil Wells for Cleaning Purposes

The oil and gas industry continuously seeks innovative solutions to improve efficiency, safety, and environmental impact. One of the latest advancements in this field is the development of a material made from cement and cross-linked polymer, designed to enhance the insulation of oil wells for cleaning purposes. This breakthrough promises to streamline maintenance processes, reduce costs, and minimize environmental risks.

The Role of Insulation in Oil Well Cleaning

Insulating oil wells is crucial during cleaning operations. Proper insulation prevents the heat loss necessary for maintaining optimal temperatures, ensuring effective cleaning and maintenance. Traditional materials used for insulation, while effective, often come with challenges such as degradation over time and limited resistance to harsh environmental conditions.

Cement and Cross-Linked Polymer (composite): A Revolutionary Material

The new material, a composite , offers significant improvements over conventional insulation methods. This innovative composite combines the robustness of cement with the flexibility and durability of polymers, creating a superior insulating material.

Advantages of the Composite

- Enhanced Durability: The cross-linked polymer adds flexibility and resilience to the cement, resulting in a material that can withstand the extreme conditions of oil wells, including high temperatures and pressures.

- Improved Insulation: The composite material provides superior thermal insulation, maintaining the necessary temperatures for efficient oil well cleaning and maintenance.

- Resistance to Degradation: Unlike traditional materials, this composite is highly resistant to chemical and environmental degradation, ensuring a longer lifespan and reduced need for frequent replacements.

- Cost-Effective: By reducing the frequency of maintenance and replacement, the composite material lowers operational costs for oil and gas companies.

How the Composite Material Works

The composite material functions by creating a robust barrier around the oil well, insulating it from external temperature fluctuations. The cement component offers structural integrity, while the cross-linked polymer enhances thermal insulation and resistance to wear and tear. This combination ensures that the oil well remains at an optimal temperature for cleaning operations, improving efficiency and effectiveness.

Applications in the Oil and Gas Industry

The primary application of this innovative material is in the insulation of oil wells during cleaning and maintenance. However, its benefits extend to other areas of the oil and gas industry:

- Drilling Operations: The material can be used to insulate drilling sites, maintaining optimal temperatures and preventing heat loss.

- Pipeline Insulation: Its durability and thermal insulation properties make it suitable for insulating pipelines, reducing energy loss and protecting against environmental factors.

- Storage Facilities: The composite can be used in storage tanks and facilities to maintain stable temperatures, ensuring the integrity of stored materials.

Environmental Benefits

In addition to operational advantages, the cement and cross-linked polymer composite offers environmental benefits:

- Reduced Waste: The material’s longevity reduces the frequency of replacements, resulting in less waste generation.

- Lower Energy Consumption: Enhanced insulation properties mean that less energy is required to maintain optimal temperatures, reducing the overall carbon footprint of oil well operations.

- Minimized Chemical Use: The material’s resistance to degradation reduces the need for chemical treatments, minimizing environmental contamination risks.

Future Prospects

The development of the cement and cross-linked polymer composite represents a significant advancement in the oil and gas industry. As research and development continue, further improvements in the material’s properties and applications are expected. This innovation holds promise for enhancing the efficiency, safety, and sustainability of oil well operations, paving the way for a cleaner and more efficient future in energy production.

The introduction of a cement and cross-linked polymer composite for insulating oil wells during cleaning operations marks a notable step forward in the oil and gas industry. Its superior durability, thermal insulation properties, and environmental benefits make it a valuable addition to current technologies. As the industry continues to evolve, such innovations will play a critical role in meeting the growing demands for energy while ensuring environmental sustainability.

For more information on this groundbreaking material and other advancements in energy technology, visit the Global Energy Prize website.

More blogs: https://sleepingsirens.com